Maximise Your Space: High-Density Warehouse Storage Solutions

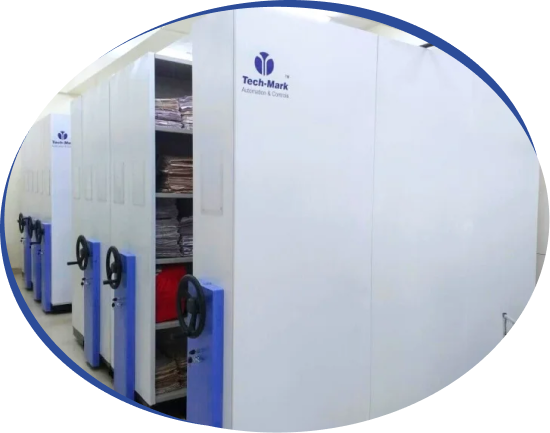

Teck Mark presents the ultimate solution to space constraints: our High-Density Mobile Compactor Storage Systems. We eliminate wasted floor space by replacing multiple fixed aisles with a single moving aisle. This clever, high-density approach allows you to effectively double your storage capacity, instantly reclaiming up to 50% of your valuable floor space. Imagine the potential: expand your operations, integrate new Warehouse Automation equipment, or create a more comfortable, productive environment.

Our Mobile Compactor Systems are engineered for precision, ensuring a perfect fit for your specific space and operational needs. We offer various secure shelving configurations, making it an ideal Warehouse Storage Equipment choice for organised and protected inventory. With smooth mobility on guided rails, accessing your stored goods is effortless and efficient. Whether you’re in pharmaceuticals, hospitals, libraries, offices, or large-scale logistics, our dynamic storage solutions are built for you.

Key Features of Our Storage Carousel System (Mobile Compactor)

- Durable and Precision-Built: Robust, high-quality rack construction is crafted with meticulous precision for exceptional strength, longevity, and reliable performance.

- Smooth and Silent Operation: Our design, featuring precision-engineered guide rails, gears, sprockets, and chains, delivers flawless, quiet movement with minimal vibration.

- Sealed, Maintenance-Free Bearings: Utilising sealed bearings pre-lubricated for life, the system ensures perpetual smooth operation and eliminates the need for ongoing maintenance.

- Secure and Protective Housing: Encased in sheet metal cladding, the system acts as a protective Bin Storage System, safeguarding stored items from dust, damage, and unauthorised access.

Techmark

CUSTOMER BENEFITS

Traditional fixed shelving wastes substantial space in unutilized aisles. Our Compactor Storage Systems eliminate this by placing shelving racks on mobile bases that glide along tracks. This powerful dynamic storage solution condenses multiple storage units into one accessible aisle, freeing up valuable floor space. This space-saving design can achieve up to 60% floor space savings compared to static shelving, or an increase of nearly 100% storage capacity within the same footprint—a critical advantage for facilities with limited space.

By utilising a single access point for multiple storage units, our Warehouse Vertical Carousel (Mobile Compactor) design significantly reduces time and movement spent navigating fixed aisles. This leads to dramatically improved storage and retrieval efficiency for your team, allowing them to locate and manage materials faster. Additionally, the optimised process reduces the reliance on extensive manual labour, translating directly into lower long-term operational costs.

Our Compactor Systems are designed for integrity. Features like durable sheet metal cladding and position locking mechanisms actively safeguard your valuable inventory. This ensures materials are protected from dust, damage, external influences, and unauthorised access, minimising potential losses and maximising inventory security.

Modern Carousel Shelving System technology, like our “Easy Glide” feature, ensures smooth, silent, and noise-free operation. This guarantees a pleasant and efficient user experience while minimising disruptions. Clear labelling and individual locking mechanisms within the Vertical Shelving System facilitate quick material location, organisation, and access, empowering employees to manage inventory quickly and efficiently.

Teck Mark Compactor Systems are modular by design, allowing them to be easily expanded to accommodate future growth and evolving storage requirements. Additional mobile units and track extensions can be seamlessly integrated to adapt to increased inventory or diversification. This scalability provides a long-term return on investment. Furthermore, the ability to configure internal pallet storage systems or bin storage system options within the mobile units ensures maximum flexibility for different types of materials.